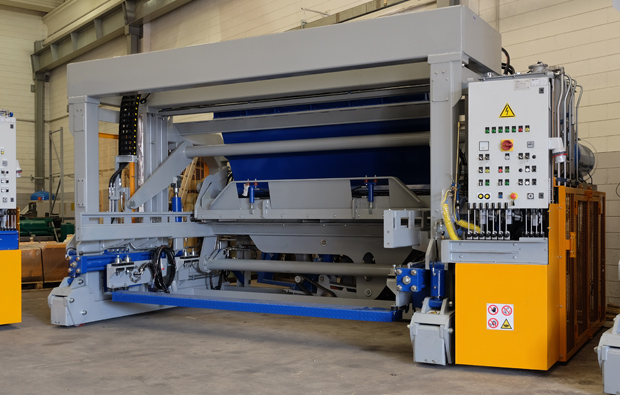

PRODUCTION OF VIBRO-DEMOULDING MACHINES

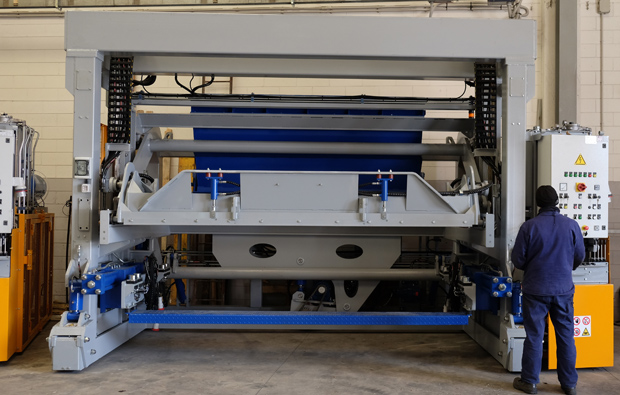

Production of vibro-demoulding machines:C.R.Stampi s.r.l. currently produces 8 models of standard machines for concrete products able to satisfy every customer need.

The vibro-demoulding machines are designed and built to improve the customers' own production

Some important features of our vibro-demoulding machines are:

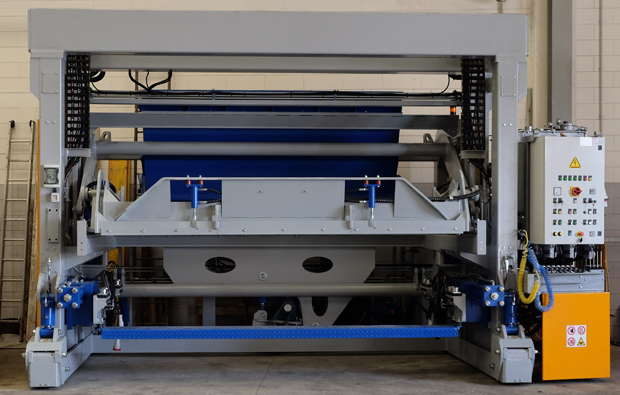

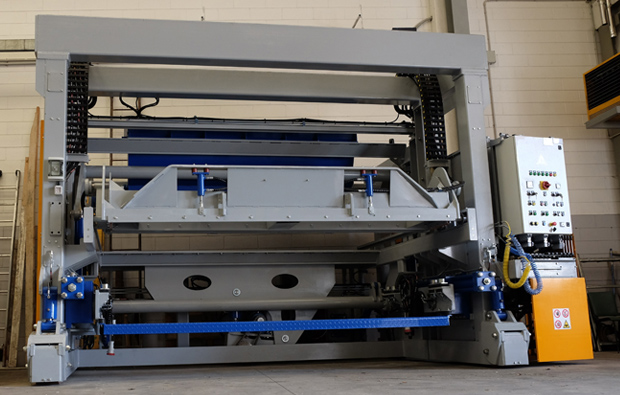

- structure in robust structurework

- double pump to separate the machine circuit oil from the oil of the moulds

- use of 4 standard vibrators on large machines, from model 200N upwards

- movement driven with hydraulic motors

- inverter to manage the motor of the hydraulic power unit

- 400 L capacity of the hydraulic power unit

- standard arrangement for heat exchanger and coil to heat the oil,

- 1950mm standard drawer feed without using extra cylinders

- mould rotation double actuator; modular for reduced maintenance costs

- mould rotation adjustment by means of special screws on the actuators that rotate the moulds

- screwed and interchangeable sectors for reduced maintenance costs

- 10" touch-screen panel for the main functions of the machine

- front wheels adjustment by front distributor lever

and many more; on request, the machines can be customised by adding the presser, opening of the hopper using the front lever distributor, systems for levelling the concrete product, quick couplings to stop oil leaks when changing moulds, etc ...

we also provide a study service for the area available for using the machine. This is to provide customers with data on the number of feasible mould outputs and therefore the actual production of the products.